Load Sign Requirements For Racking

Load signs for racking units play an important role in ensuring that your storage racks are used correctly, but many people ask "are they really required for shelving units?".

Load signs for racking units play an important role in ensuring that your storage racks are used correctly, but many people ask "are they really required for shelving units?".

To answer this question we need to look at the HSE guidelines for safety in the workplace. These guidelines state that all employers have a legal responsibility to inform employees of how to correctly use equipment in the workplace. In order to use shelving and racking units in the right way, users need to be aware of the all-important load capacities. These weight loadings apply to not only the individual shelves but the whole racking structure too.

Overloading can cause stress on individual components beyond that of their original design - leading to obvious failures such as broken shelf decks and bent support beams. However, more serious problems can occur when overloaded shelving units cause unseen damage to the racks which can cause structural issues, this could lead to serious problems like bent frames and even framework collapsing!

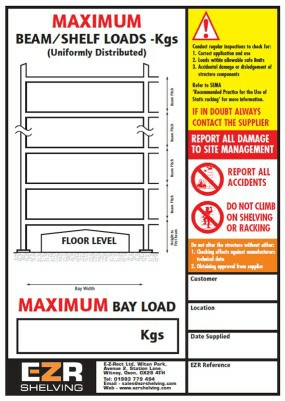

The easiest way to comply with the health and safety regulations is to display load signs in prominent positions. This way you can ensure that all employees and indeed visitors to the warehouse/stockroom can use the racking safely. Load signs can also be complimented via the use of shelf beam labels.

The images here show two methods of displaying loading data on racking and shelving in the workplace. Full load notices are often combined with shelf load labels (shown below) to make it clear how much can be loaded onto the racks. The need to show weight loading information applies to both light duty shelves/rails and heavy duty racking. If you require any help or advice on this issue please contact us on 01993 779494.